Ensuring safety, integrity, and quality in every package

Premium Sterile Packaging Solutions for the Medical Industry

Our parent company Yogi Kripa Medi Chem started in July 1997. Yogi Kripa was among the first few Indian companies to introduce the concept & products related sterilization packaging, Monitoring & Documentation systems as per the -ISO, EN & CE standards to the Hospital & Pharmaceutical Industry.

At Steri Protek, we understand the critical importance of sterile packaging in the medical industry. Our products are meticulously designed to meet the highest standards, ensuring the safety and integrity of your medical devices.

About Us

Leading the way in sterile packaging solutions, ensuring safety and quality in the medical industry since 1997.

Our Products

Discover our comprehensive range of high-quality sterile packaging solutions designed to meet the diverse needs of the medical industry.

Get In Touch

Get in touch with us for premium sterile packaging solutions tailored to your needs.

About Us

Pioneering Sterilization Packaging Since 1997

Given the positive trends in the market and our experience with the product range, we formed a new company under the name of Yogi Kripa Steriprotek Packaging (P) Ltd to set up a State of the Art Manufacturing facility to provide medical packaging solutions to our pharmaceutical, medical device and healthcare customers with a consistent and reliable supply chain for of premium sterile barrier systems for safe packaging

The Facility is MDR 2017 (CDSCO Guidelines) and ISO 13485 certified and complies with guidelines for Class 8 Cleanrooms according to ISO 14644 part 1-3.

40+

Years Of Experience

5

Product Range

300+

Cities Served

100%

Quality Assurance

Uncompromising Quality Assurance

At Steri Protek, we are committed to delivering the highest quality in sterile packaging solutions. Our rigorous quality control processes ensure that every product meets stringent industry standards.

Visual Inspections

Ensuring no defects such as holes, tears, or thinning in packaging materials.

Bubble Leak Tests

Detecting any potential leaks to maintain the sterility of the packaging.

Microbial Challenge Tests

Verifying the packaging's ability to prevent microbial contamination.

Seal Integrity Testing

Confirming the strength and reliability of seals to protect the contents effectively.

Pouches generally fall in one of three medical packaging categories:

Breathable Pouches

These are Suitable all kinds of sterilisation viz. Ethylene Oxide (EO), Gamma, Steam or H2O2. These are made up of Medical Grade Paper or Tyvek along with different grades of laminated plastic films.

Film-To-Film Pouches

These are best suited with gamma radiation and electronic beam sterilization.

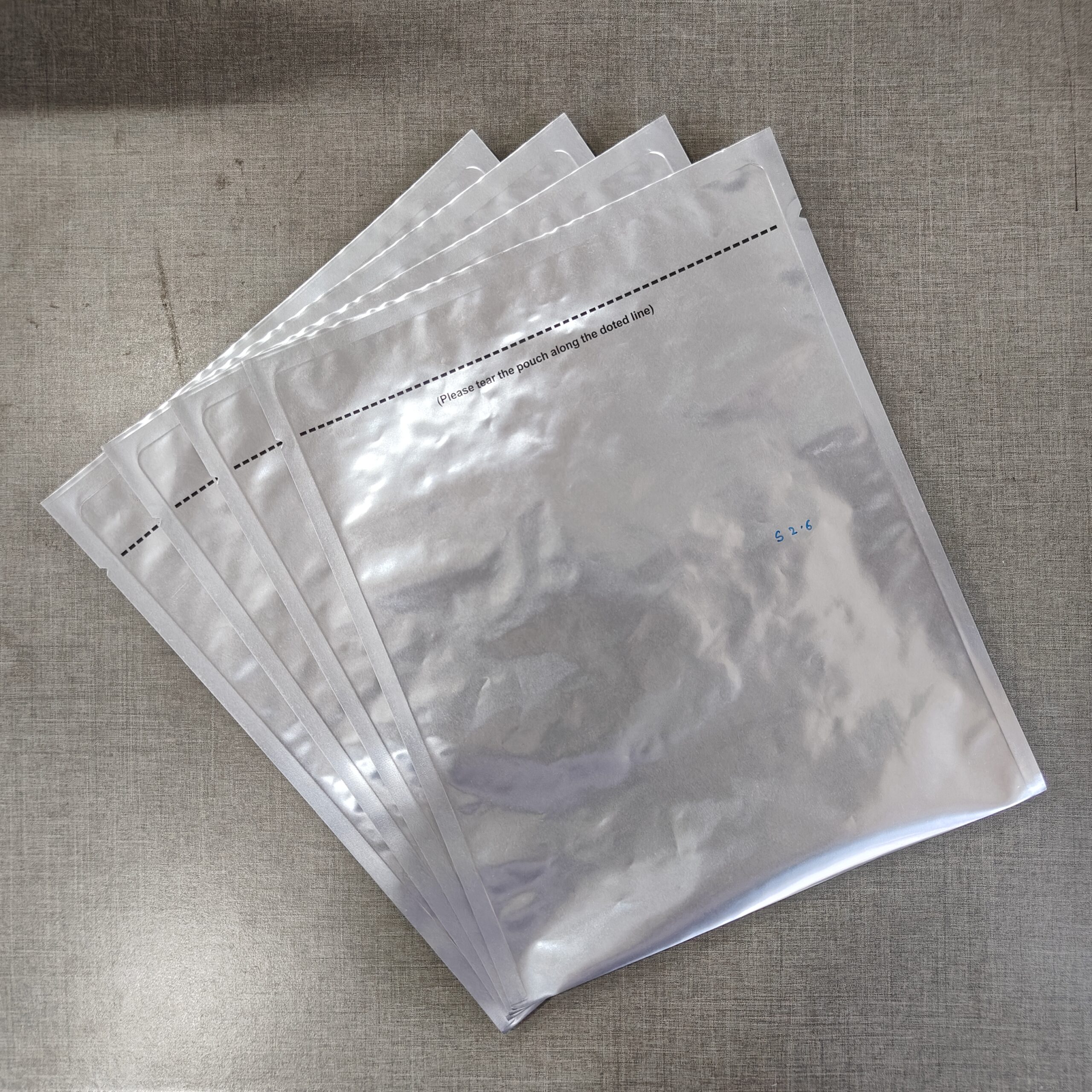

High Barrier Pouches

It prohibit light, oxygen, and moisture from penetrating packages and causing device degradation. High barrier pouches are particularly effective in maintaining the integrity of cardiac catheters, guidewires, implants, moisture sensitive drug delivery systems and transdermal patches).

Medical / Sterilization Pouches & Reels:

► Medical Packaging Pouches are a key solution for medical device sterilization, protection, and safety. Each design takes specific device, characteristics and application environments into consideration.

► Medical packaging pouches bring together two webs of engineered materials that are heat-sealed on three sides to form an enclosure that can be produced in a wide range of shapes and sizes, and provide enhanced product protection. The materials used depend upon device weight, puncture resistance, and end user requirements such as visibility and peelability.

Subsribe To Our Newsletter

Stay in touch with us to get latest news and special offers.

Address

YOGI KRIPA STERIPROTEK PACKAGING PVT. LTD. Unit No 4 & 5, Ujagar Chambers, Deonar, Mumbai, Maharashtra 400088.

Call Us

9820135461

Email Us

manish.gupta@yogirkripa.com